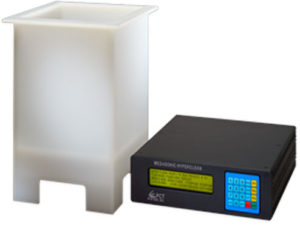

Megasonic Cleaning Applications

Megasonic cleaning is utilized for several applications:

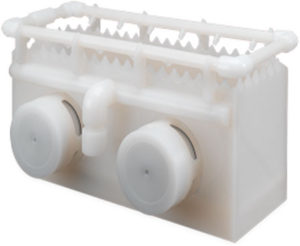

Disk Drive components

When large amounts of media need to be cleaned quickly, the unsurpassed power and intensity of megasonic processing removes even stubborn particles with quick efficiency. When small and discrete three-dimensional parts require the removal of the smallest particles, megasonic processing sends energy through and across parts and substrates to clean in those hidden recesses.

Electrochemical processing

Whether plating, polishing/etching or grid-xing surface layers, concentration polarization and fluid stagnation in trenches and vias can lead to slow diffusion limited processing. Megasonic processing allows sonic energy to transfer through substrates and across features to maximize bulk fluid movement even in small trenches and recesses to minimize diffusion limiting stagnant locations.

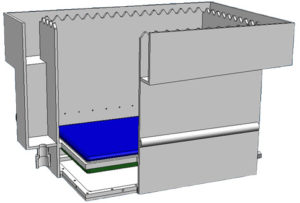

Flat and flex panel

When ample areas require sonic energy, megasonic processing with wide area megasonic nozzle technology provides the processing fluid directly to the substrate surface simultaneously with the sonic energy to uniformly process large areas efficiently.

LED

PCT Systems, Inc. offers sonic assisted and non-sonic tanks for use in LED manufacturing. High temperature quartz constant temperature baths, and megasonic assisted tanks for post scribe clean applications.

MEMS

Developing resist and wet etching substrates can be a problem because of the discrete features and tortuous paths that the processing liquid must follow. Fluid stagnation producing dead areas can lead to locally slow diffusion limited mass transfer. Megasonic processing can allow sonic energy to transfer through substrates and across discrete devices eliminating stagnant areas and increasing mass transfer rates.

Nanoscale Particle

Cleaning of sub 50 nanometer particles is becoming a real challenge. With megasonics processing technologies multiple frequencies up to 2 MHz can be utilized simultaneously to provide special processing modes to clean even the smallest particles on the most delicate features.

Optics

Sensitive optics can be damaged by low frequency. Ultrasonic tanks have the potential to cause crazing and cracking. PCT Systems, Inc. offers a wide range of high frequency Megasonic tanks for cleaning optics after various lapping and polishing processes.

Resist Stripping

When it is time for stripping resists, megasonic processing can be combined with dissolved ozone or other chemicals in various liquids to produce the highest gas transfer rates available. Megasonic processing can disrupt thin liquid boundary layers to enhance mass transfer of various gases and liquids needed for enhanced processing.

Solar Cell Fabrication

When rapid particle removal, increased etch rates and substrate cleaning is required on large scale substrates, megasonic processors can assist in new manufacturing technologies.