概述

单击并拖动以旋转

White Knight PSD系列气体驱动的双膜片泵之所有具有防酸的特性是其由特氟龙或聚乙烯材质制作的。 PSD系列泵被用在腐蚀性的毒性的液体,如酸,碱胶,水、油漆、树脂、油墨、或污水,食品,化妆品,研磨液。

该泵可在3/8、1/2、1、或1-1/2英寸型号。 些产品的特点是高质量的加工设计,独特的密封表面和紧密的螺纹配置,以确保稳定、可靠的性能和卓越的产品控制。 可以配置在各种材料,以满足最耐磨,温度,和化学品的要求。 独特的密封方式并且能够提供较高的流量,同时最大的减少空气消耗量和工作噪音。 该泵具有自吸泵、除冰的供气系统。

PSD系列泵易于安装、操作和维修。 无需维护和保养,可以最大程度的减少因为维护或维修的成本,减少停机时间增大生产时间。 它们只需要最少的零件来重建,并且可以在情况下重建也将需要其他的隔膜泵进行替换,这增加了泵的寿命和减小的总体拥有成本。

维修可能需要取决于出勤率

特点和优点

- PTFE液体通道的

- 机加工设计(not molded)

- 自吸泵、除冰的供气系统

- Positive seat-check 改善吸力

- 可移除气动马达无需购买一个全新的泵

- 我们质量保证源自优秀设计和高效的制造

- 聚丙烯泵本体

- 超模压 PTFE/EPDM 隔膜

- 蒙打能力是可行的

- 干打,干燥的能力

- 占用空间小;易于安装和服务

- 耐用可翻新的设计使用最少的零件

- 设置多个液体入口/出口的方向

- 可最大程度地减少工厂环境噪声和驾驶员疲劳

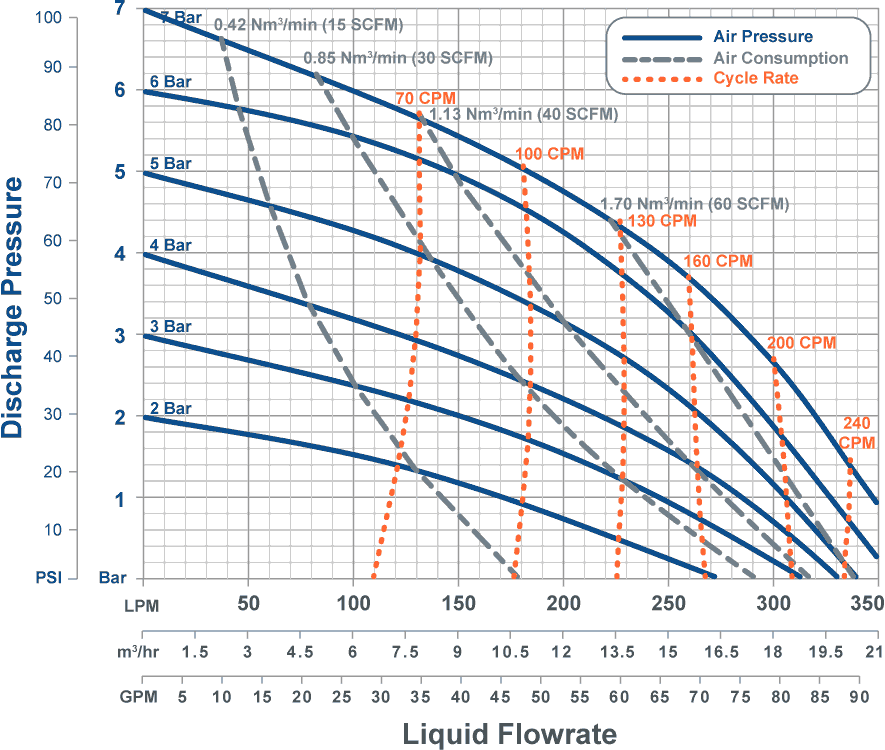

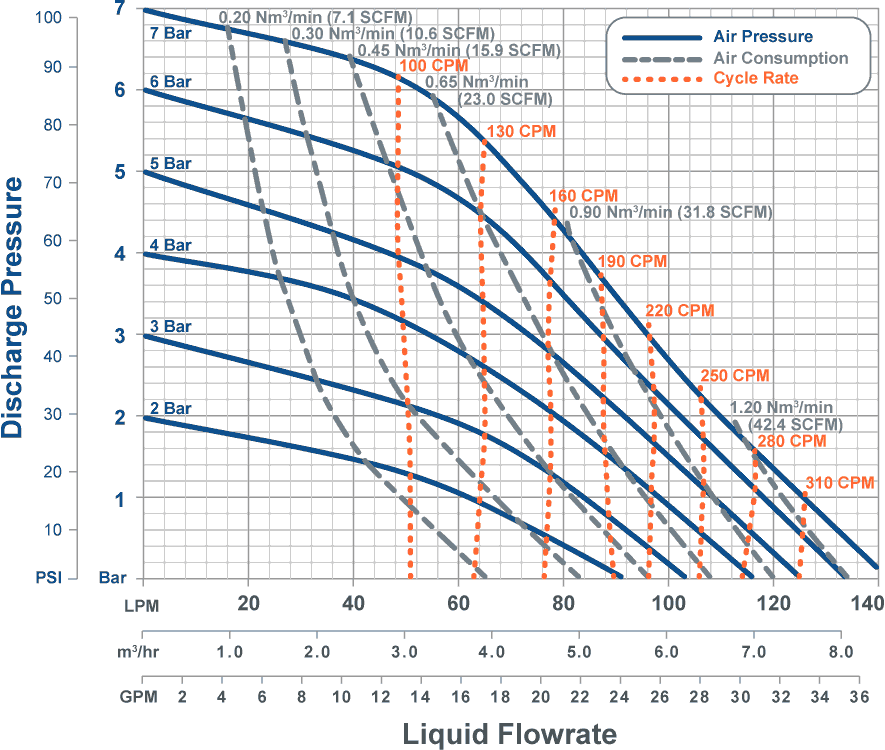

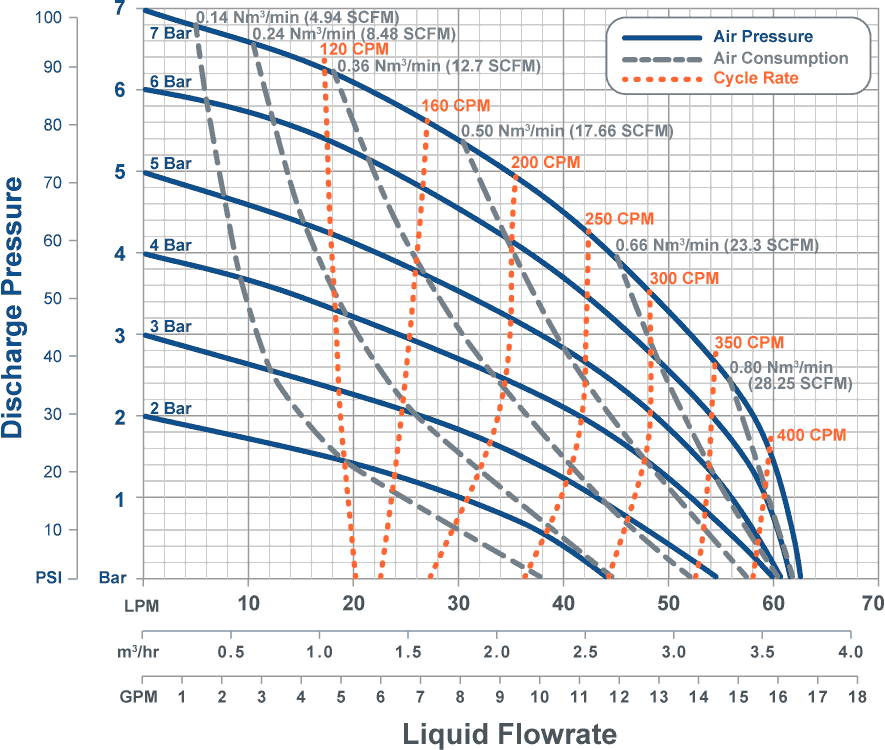

性能曲线

PSD24 性能曲线

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PSD16 性能曲线

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PSD08 性能曲线

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PSD06 性能曲线

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

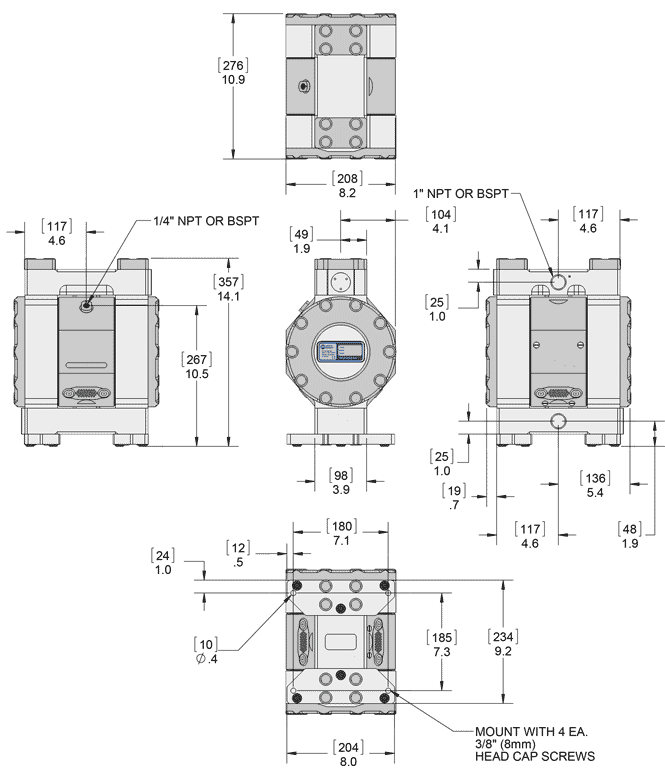

尺寸

规范

泵型号 |

PSD06 |

PSD08 |

PSD16 |

PSD24 |

|---|---|---|---|---|

| 最大流量* | 28 升/分钟 |

63 升/分钟 |

142 升/分钟 |

372 升/分钟 |

| Displacement Per Cycle* |

0.07 升 |

0.16 升 |

0.56 升 |

1.64 升 |

| 气源接口 | 3/8 in NPT |

1/2 in NPT |

1 in NPT |

1-1/2 in NPT |

| Max. Size of Passable Solids | 2 毫米 |

4 毫米 |

5 毫米 |

8 毫米 |

| 吸升高度 (Dry)* | 3 米 |

3 米 |

4 米 |

5 米 |

| 吸升高度 (Wet)* | 9.5 米 |

9.5 米 |

9.5 米 |

9.5 米 |

| Sound Pressure** | 60.2 dB(a) 66.1 dB(a) |

61.7 dB(a) 82.0 dB(a) |

66.6 dB(a) 83.3 dB(a) |

84.2 dB(a) 89.8 dB(a) |

| Sound Power** | 51.7 dB(a) 58.1 dB(a) |

54.5 dB(a) 74.8 dB(a) |

61.6 dB(a) 78.3 dB(a) |

83.2 dB(a) 91.1 dB(a) |

| 重量 | 3.1 kg |

9.0 kg |

18.2 kg |

43.2 kg |

| 最高温度 | 100°C |

|||

| 最大供气压力 | 7 Bar (100 psi) |

|||

| 最小启动空气压力 | 2 Bar (30 psi) |

|||

| Fluid Path Materials | PTFE |

|||

| Diaphragm Materials | Over-molded PTFE/EPDM |

|||

| Check Ball Materials | PTFE |

|||

泵型号 |

PSD06 |

PSD08 |

PSD16 |

PSD24 |

*May vary depending on materials. Suction lift diminishes over time. Minimize height for best performance.

**Sound Levels measured at 7 Bar 100 CPM (top) and 7 Bar maximum CPM (bottom) in accordance with ISO9614-2:1997.