High-Purity PTFE Valve Manifolds for Aggressive Chemicals

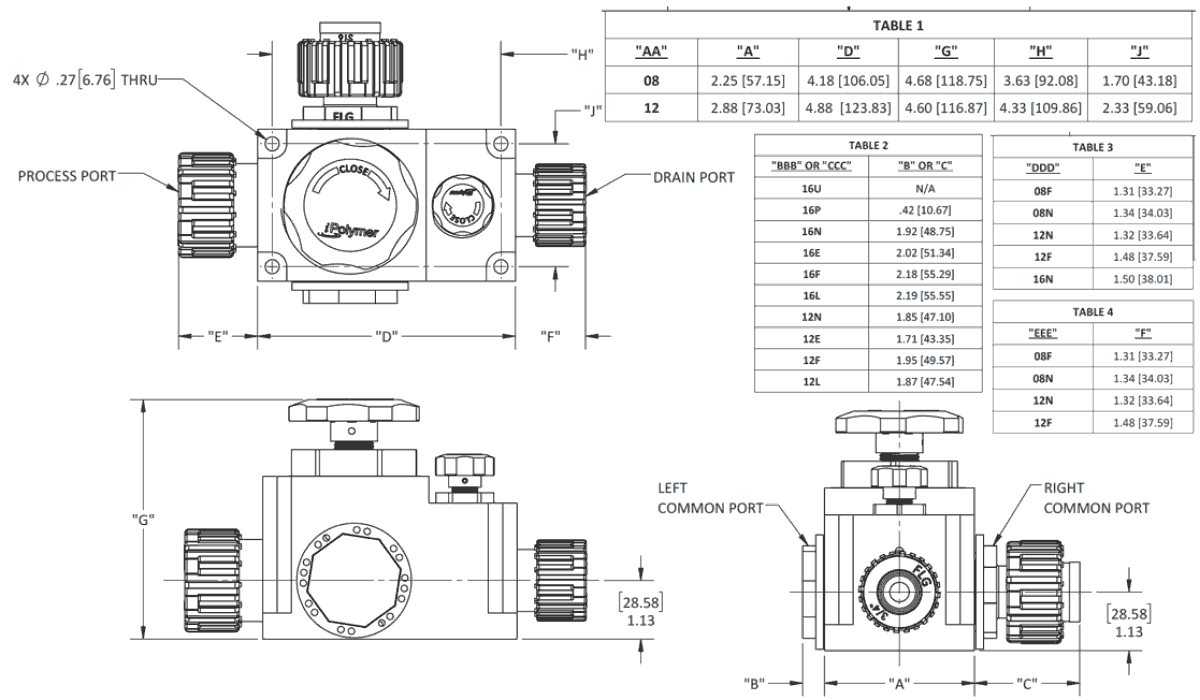

iPolymer High-Purity Valve Manifolds (HVM) feature 100% virgin PTFE, PFA and M112 wetted flow path ideally suited for aggressive chemical applications common in Semiconductor valve boxes and distribution systems. Their simple, nonmetallic construction consist only of PTFE, PVDF, PFA and PEEK ensuring reliable, long lasting performance. The primary Manual valve directs flow from the common ports to the process port (typically North) and the drain valve allows the operator to purge or sample the process (typically South). iPolymer HVM-8 and HVM-12 are direct replacements for the Parker MV-8 Series valves.