개요

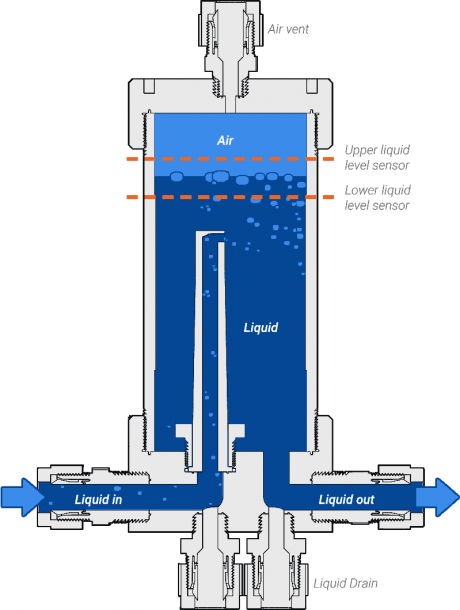

White Knight debubblers reduce bubbles from high-purity chemical delivery and wafer process systems. They redirect flow to the surface so that bubbles rise out of the fluid. They feature 4-in inside diameters for greater debubbling surface area. 누수없는, 가공된 설계, Tongue 와 Groove seals. Liquid level sensor options.

기능 및 이점

- 공정에 안전한 PTFE 및 PFA 로 구성된 유체경로

- ≤ 7 Bar (100 psi) 압력 high flow rates for faster processes

- ≤ 100°C 또는 210°C 최대 유체 온도

- 누수없는, 가공된 설계, Tongue 와 Groove seals

- Easy setup and maintenance without welding

- Ideal for chemical delivery and wafer process debubbling

More Information:

CBA 시리즈 Debubblers

CBA 시리즈 debubblers are available in various connectable pipe lengths with models capable of up 1-6 liter volumes. They offer additional mounting and liquid level sensor options.

- 100°C 최대 유체 온도

- 누수없는, 가공된 설계, Tongue 와 Groove seals

- 최대 1-6 리터 용량의 모델 공급

- Liquid level sensor and mounting options

CBU 시리즈 Debubblers

CBU 시리즈 debubblers capable of up to 210°C (410°F) fluid temperatures. They feature Synchro-Thread™, tongue-and-groove seals, and dual-static crush seals to ensure safe, reliable operation at high-temperatures.

- Synchro-Thread™ enables 210°C 최대 유체 온도

- 누수없는, 가공된 설계, Tongue 와 Groove seals

- 이중-고정 압착 Seal

- 최대 1 리터 용량의 모델 공급

- Liquid level sight tube options

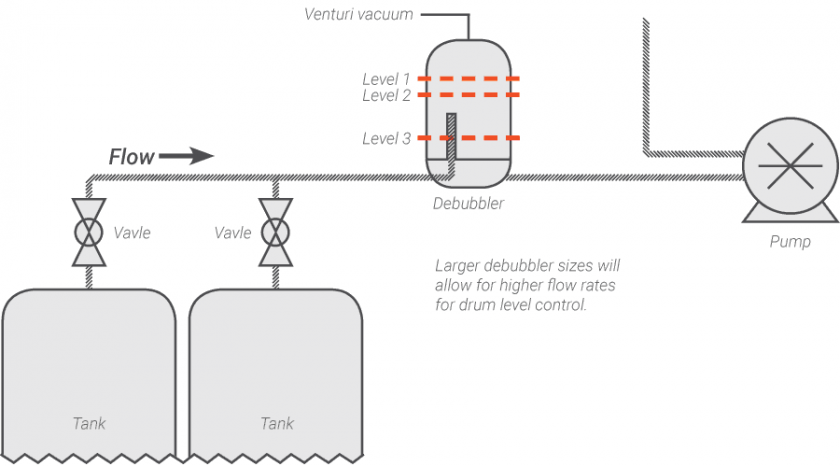

펌프 운전

White Knight debubblers redirect flow upward and slows the fluid so that air bubbles rise within the chamber. As air collects at the top, the liquid level drops until the lower sensor detects a low liquid level and signals a valve to open to releases air via the drain vent. As air vents, the liquid level rises until the upper sensor detects a high liquid level and signals the valve to close.

제품 비교

| Debubbler 모델 | ||

|---|---|---|

PTFE, PFA 유체 경로 |

||

최대 유체 온도 |

100°C |

210°C |

최대 공압 |

7 Bar (100 psi) |

7 Bar (100 psi) |

Maximum Volume |

1-6 L |

1 L |

Tongue-와-Groove Seals |

||

이중-고정 압착 Seal |

||

Synchro-Thread™ |

||

Mounting Bracket Options |

1-3 brackets or base mount |

Base mount |

Sensor Options |

1-3 sensors on body or brackets |

Sensors on liquid level sight tube |

보증 |

2 년 보증 |

2 년 보증 |

온도

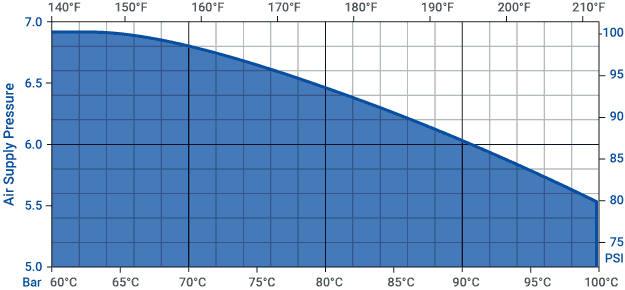

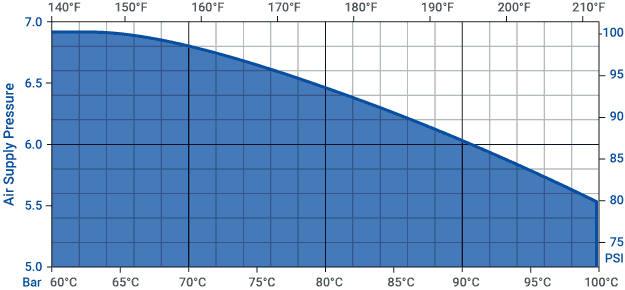

CBA 온도

CBA 온도

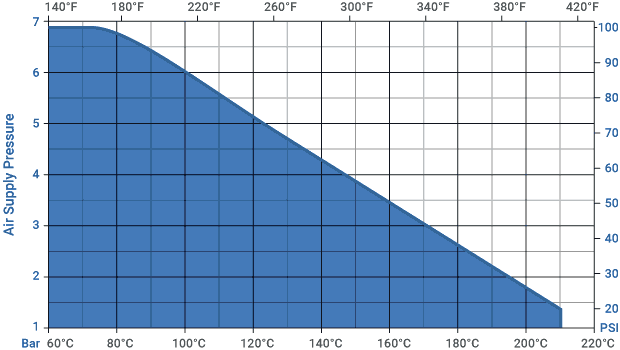

CBU 온도

Debubbler Applications

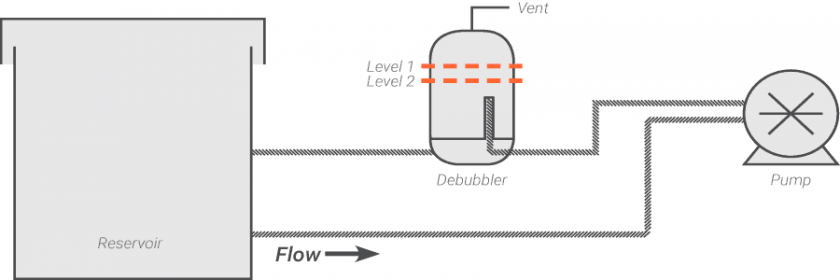

Remove Bubbles After Pumps

Chemical enters the debubbler through the stand tube. Level sensors 1 and 2 control the collected air volume in the debubbler. Collected air exits through the vent line.

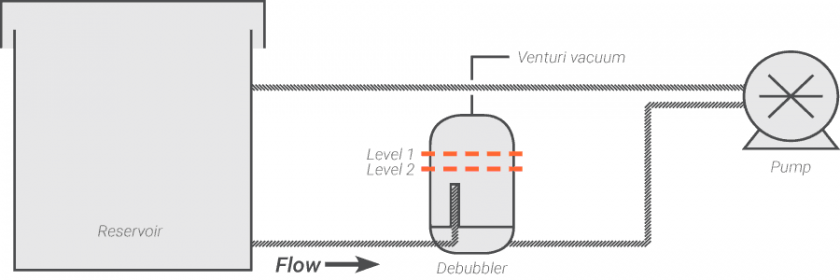

Remove Bubbles Before Pumps

Chemical is pulled into the debubbler through the stand tube. Level sensors 1 and 2 control air collection level to purge the collected air, a vacuum is required to remove collected air. This can be achieved using a venturi-type vacuum.

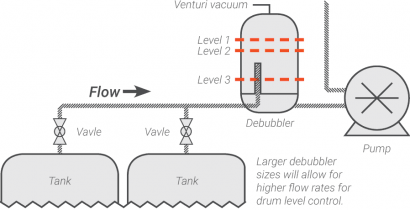

Automate Drum Change

Level sensors 1 and 2 act to keep bubbles from the drums from continuing through to the pump. Level 3 indicates an empty drum. This can be used as an automatic drum switch or as a drum empty signal.

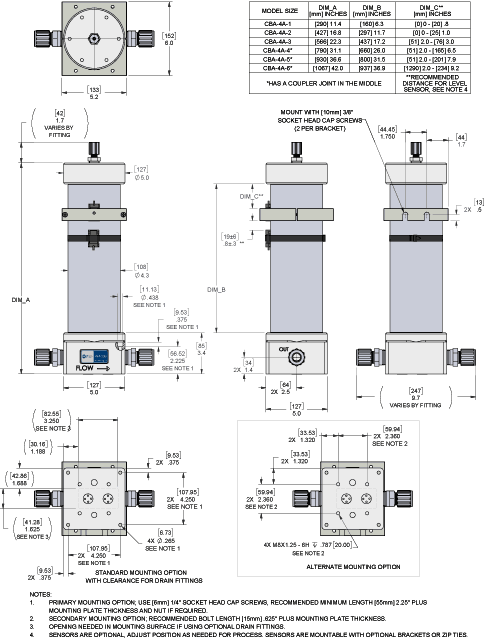

치수

치수 [mm] 인치

CBA 치수

| mm (in) | A | B |

|---|---|---|

| 1 liter | 295 (11.6) | 132 (5.2) |

| 2 liter | 434 (17.1) | 272 (10.7) |

| 3 liter | 572 (22.5) | 409 (16.1) |

| 4 liter | 798 (31.4) | 632 (24.9) |

| 5 liter | 935 (36.8) | 772 (30.4) |

| 6 liter | 1074 (42.3) | 980 (38.6) |

CBU 치수