概述

CBU系列的气液分离器可减少化学药剂输送以及晶片加工系统中的气泡,供液温度高达210°C。 They redirect flow to the surface so that bubbles rise out of the fluid. 它们具有可配置的接口连接方式和榫槽密封。 可安装液位传感器。

特点和优点

- 过程安全的PTFE和PFA液体通路

- 最高7公斤(100PSI)压力

- 耐高压的能力为更快的工艺提供大流量

- 最高210度

- 化学药剂输送以及晶片加工系统中的气液分离

- 具有Synchro-Thread™螺纹的聚四氟乙烯材质的

- 榫和槽型密封件 技术是最可靠和可重复使用的

- 无泄漏双密封圈挤压式密封

- 管提供简单的安装和维护并且无需焊接

操作

CBU系列的气液分离器可改变上升的流量减缓流体的流速,使得气泡在腔体内上升。 当空气聚集在顶部时,液位下降直到下液位传感器检测到低液位信号并给排气阀发出打开信号,通过排气口释放空气。 随着空气排出,液面上升,直到上液位传感器检测到高液位信号,并指示阀门关闭。

Debubbler Applications

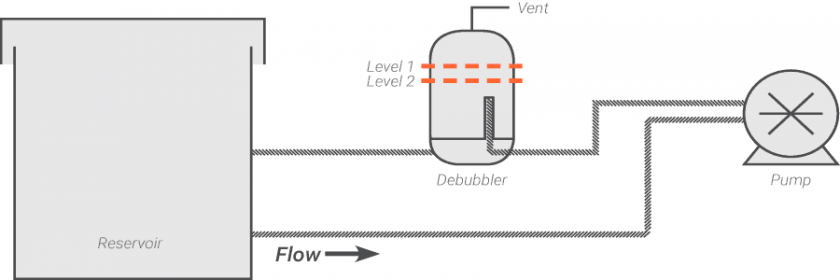

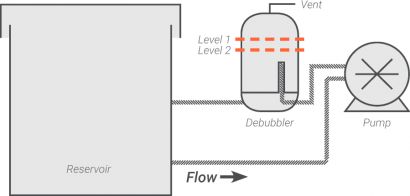

Remove Bubbles After Pumps

Chemical enters the debubbler through the stand tube. Level sensors 1 and 2 control the collected air volume in the debubbler. Collected air exits through the vent line.

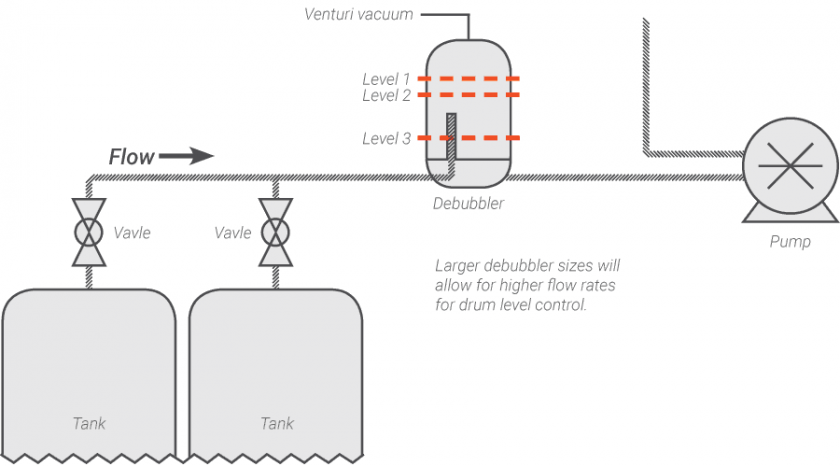

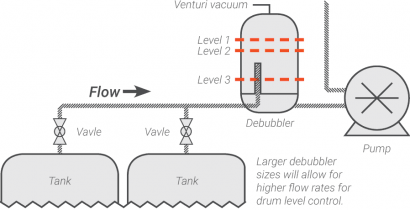

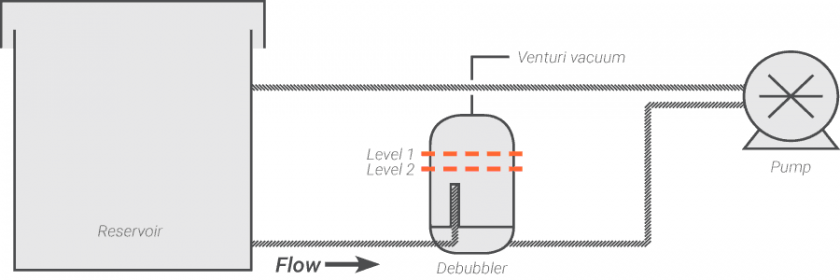

Remove Bubbles Before Pumps

Chemical is pulled into the debubbler through the stand tube. Level sensors 1 and 2 control air collection level to purge the collected air, a vacuum is required to remove collected air. This can be achieved using a venturi-type vacuum.

Automate Drum Change

Level sensors 1 and 2 act to keep bubbles from the drums from continuing through to the pump. Level 3 indicates an empty drum. This can be used as an automatic drum switch or as a drum empty signal.