概述

CBU系列的液氣分離器可減少高純度化學品輸送和晶圓加工後所產生的氣泡. They redirect flow to the surface so that bubbles rise out of the fluid. Their tongue-and-groove seals and dual-static crush seals ensure safe, reliable operation.

特點和優點

- 過程安全的PTFE和PFA液體通路

- 最高7公斤(100 psi)壓力能為更快的製程提供高流量

- 最高210°C度

- 去除輸送化學品及晶圓加工後的氣泡

- Synchro-Thread™螺紋的最高可以在210°C度使用

- Tongue和Groove 密封技術是最可靠和可重複使用的

- 雙層的積壓式密封以防洩漏

- 無需焊接即可輕鬆進行設置和維護

操作

CBU系列液氣分離器向上重新引導流體並減慢流體的速度,使氣泡在腔室內上升. 當空氣聚集在頂部時,液位下降,直到下部傳感器監測到低液位並且發送閥門打開的訊號以通過排放口釋放空氣. 作為通風口,液位上升,直到上部傳感器監測到高液位並發送閥門關閉的訊號.

Debubbler Applications

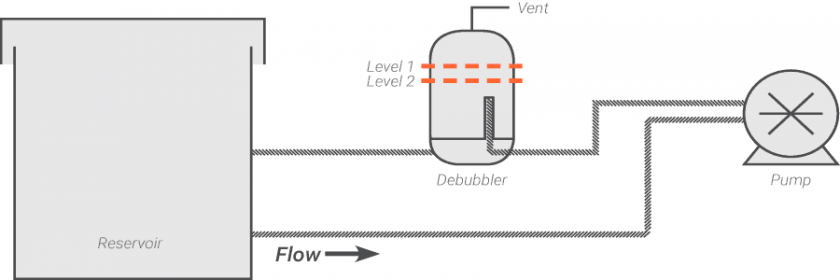

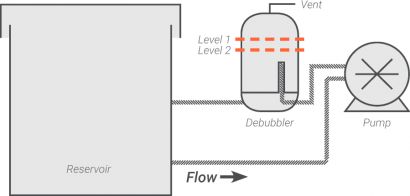

Remove Bubbles After Pumps

Chemical enters the debubbler through the stand tube. Level sensors 1 and 2 control the collected air volume in the debubbler. Collected air exits through the vent line.

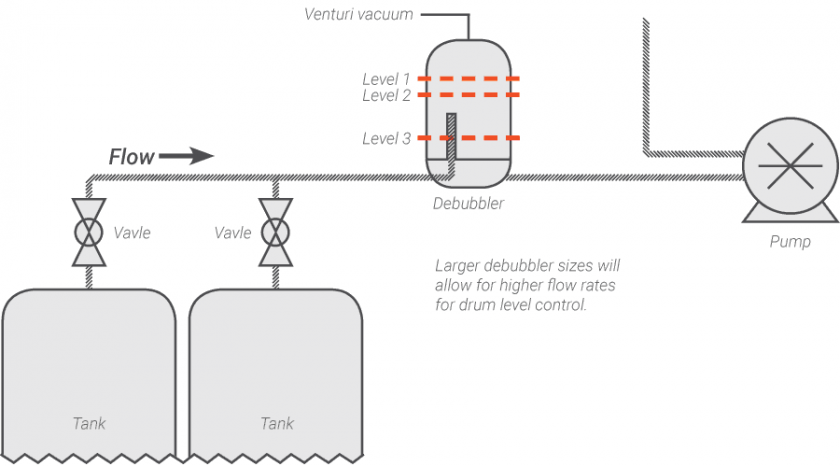

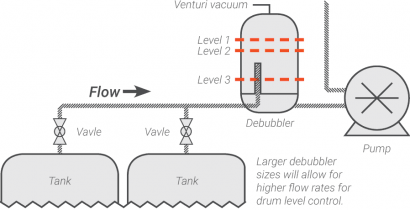

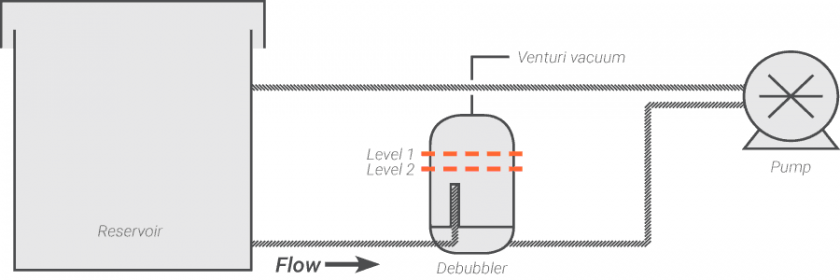

Remove Bubbles Before Pumps

Chemical is pulled into the debubbler through the stand tube. Level sensors 1 and 2 control air collection level to purge the collected air, a vacuum is required to remove collected air. This can be achieved using a venturi-type vacuum.

Automate Drum Change

Level sensors 1 and 2 act to keep bubbles from the drums from continuing through to the pump. Level 3 indicates an empty drum. This can be used as an automatic drum switch or as a drum empty signal.