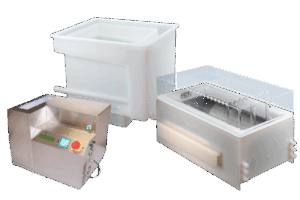

White Knight offers Imtec Accumeg™ and PCT HyperClean™ systems. PCT and Imtec are leaders in advanced megasonic cleaning technology, offering high-frequency, non-damaging cleaning solutions for semiconductors, optics, medical implants, and industrial parts. Both solutions are ideal for high-purity, precision cleaning applications.

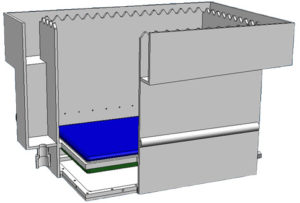

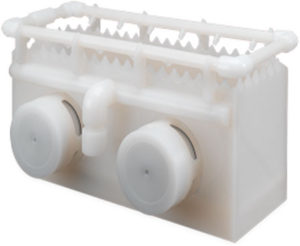

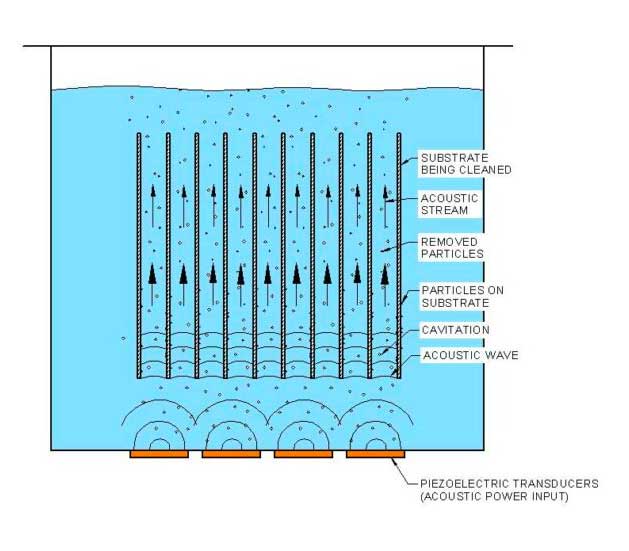

Imtec’s Accumeg™ systems efficiently deliver continuous megasonic energy across the entire process tank to ensure fast, uniform cleaning and prevent particle reattachment. Unlike pulsed systems, its full-coverage transducer array avoids energy loss from shadowing or sequencing. Accumeg combines proven reliability with low maintenance.

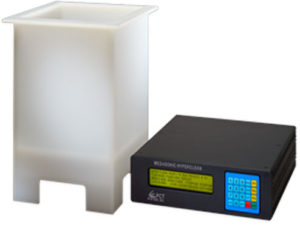

PCT’s HyperClean™ systems features moving-beam and phase-shifting technology, achieving over 90% acoustic energy efficiency, housed in compact, high-purity quartz vessels. The systems incorporate PCT’s unique generators and transducers for reliable submicron cleaning at elevated temperatures, while reducing chemical use and cleanroom footprint.

These systems sets the industry standard in high-purity, high-power megasonic cleaning and offer reliable, innovative solutions for a wide range of applications, including semiconductors, optics, MEMS, LEDs, solar cells, and flat panels.