Overview

click+drag to rotate

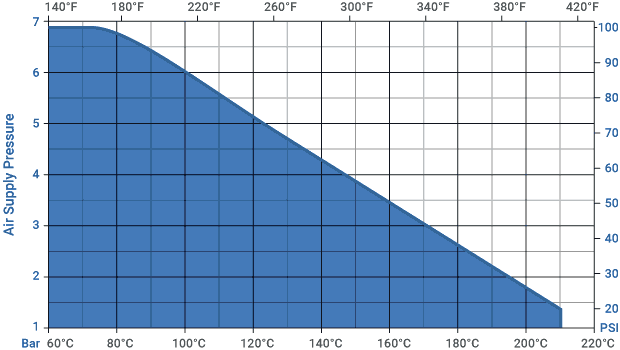

PFU Series pumps are the ideal solution for ultra-high temperature and ultra-pure recirculation or delivery applications where fiber optic sensors are required for optimum systems control. These PTFE and PFA pumps are completely metal free and operate with fiber optic sensors and an external solenoid valve. They perform safely and reliably running continuously throughout their two-year warranty. They offer air supply pressures up to 7 Bar (100 psi) and operate in thermal cycling applications with fluid temperatures up to 210°C (410°F).

The pumps are available in three models, PFU030, PFU060 and PFU140, which are capable of maximum flow rates of 30, 60 and 140 lpm, respectively.

Features & Benefits

- 100% Metal-Free

- Process-safe PTFE and PFA flow paths

- Leak-proof, machined design

- PTFE heads with Synchro-Thread™

- No elastomer O-rings, no leaks, never retorque

- No lubrication in shift mechanisms

- No electric motors, which generate heat

- Safe, leak-free operation due to no-metal design

- Minimal parts for durable design

- Class 100 cleanroom assembly, testing, and packaging

- Easy to install and service

- Robust bellows offer supply pressure of 7 Bar (100 psi)

- No preventative maintenance during two-year warranty

- Various liquid connection options

Operation

PFU Series pumps operate with a solenoid valve and fiber optics that optimize stroke timing by shifting the pump quickly and efficiently to increase durability.

Pump Control Options:

Supply Air

Exhaust Air

Ambient Air

Shift Signal

Liquid Suction

Liquid Discharge

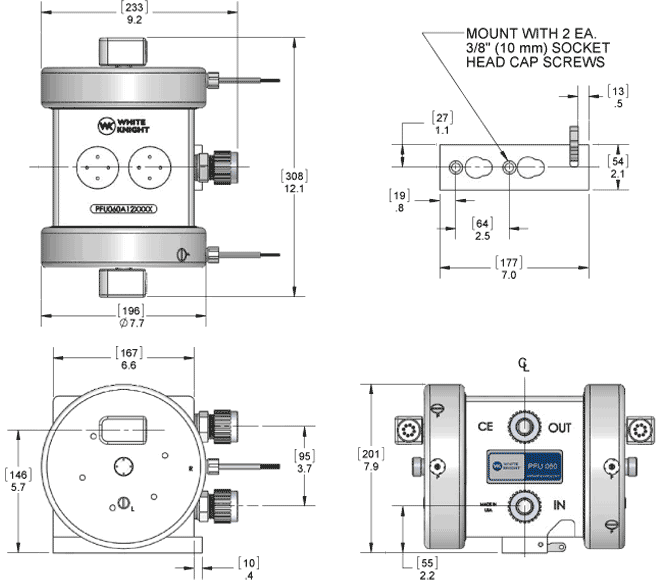

Performance & Dimensions

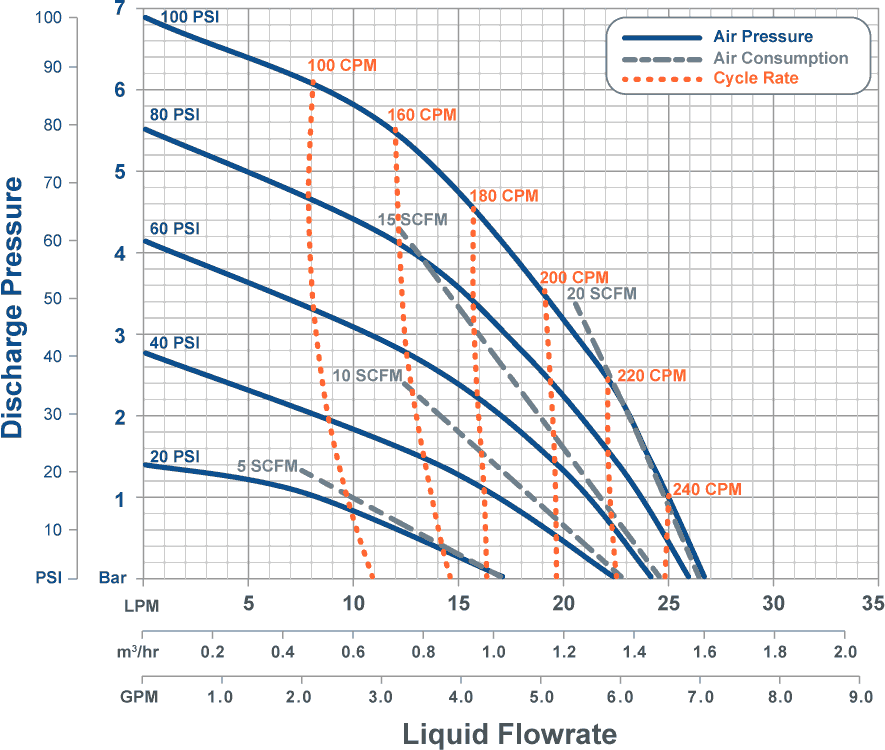

PFU030 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PFUSD030 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

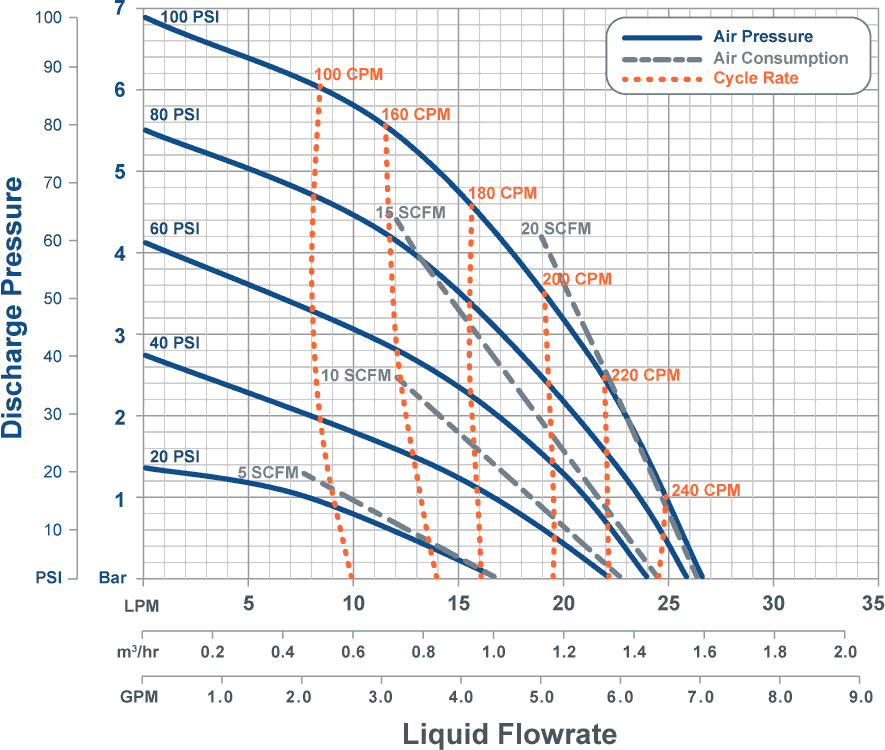

PFU060 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PFUSD060 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PFU140 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

Specifications

Model |

PFU030 |

PFU060 |

PFU140 |

|---|---|---|---|

| Flow Rate* | 26.4 lpm 6.97 gpm |

65.8 lpm 17.38 gpm |

139.8 lpm 36.93 gpm |

| Size of Air Connection | 1/4-in FNPT |

1/4-in FNPT |

3/8-in FNPT |

| Displacement Per Cycle* | 0.089 liters 0.024 gal |

0.216 liters 0.057 gal |

0.500 liters 0.132 gal |

| Cycles Per Minute* | 336 max |

318 max |

253 max |

| Weight | 5.5 kg (12.1 lb) |

13.7 kg (30.3 lb) |

20.4 kg (45.0 lb) |

| Suction Lift* | 1 m (3 ft) |

1 m (3 ft) |

1 m (3 ft) |

| Sound Pressure** |

69.54 dB(a) 66.58 dB(a) |

82.74 dB(a) 82.61 dB(a) |

77.90 dB(a) 79.56 dB(a) |

| Sound Power** |

58.44 dB(a) 65.52 dB(a) |

71.92 dB(a) 73.84 dB(a) |

73.78 dB(a) 76.10 dB(a) |

| Max Temperature | 210°C (410°F) |

||

| Max Pressure | 7 Bar (100 psi) |

||

| Fluid Path Materials | PTFE, PFA |

||

| Non-Fluid Path Materials | PTFE, PFA |

||

| Stroke Detection Options | Fiber optic with or without sensor, or solid state pressure switch |

||

| Leak Detection Options | Fiber optic with or without sensor, or conductivity |

||

| Electronic Control | Available |

||

Model |

PFU030 |

PFU060 |

PFU140 |

*May vary by configuration or system. Suction lift diminishes over time. Recommended installation level less than 3 ft above source.

**dB Level at 100 psi 50 CPM (top) and 100 psi maximum CPM (bottom). Sound Levels measured in accordance with ISO9614-2:1997.

***Dry-run capable PFUSD pumps require flooded suction and may have a reduced warranty. Contact White Knight for details.