Overview

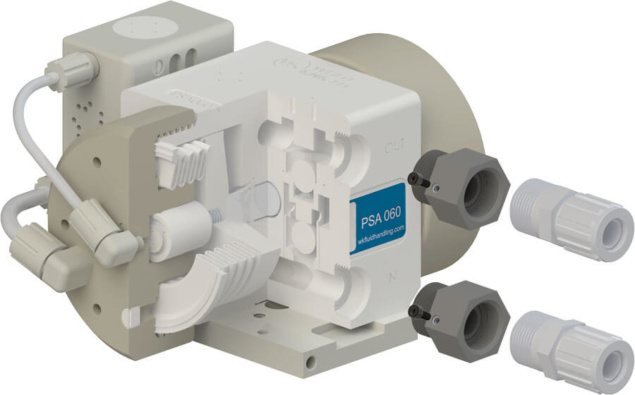

Insert grounding adapters between the fluid ports of White Knight high-purity pumps and their liquid fittings. Adapters must be used at both inlet and outlet connections, and grounded. Grounding adapters are conductive PTFE.

Use White Knight fiber optics for leak and cycle sensing to ensure safe and reliable operation.

Compatible Pumps

White Knight grounding adapters are compatible with all White Knight high-purity pumps and fittings, but they should not be used with pumps that are controlled with proximity sensors. See below for compatible pump models.

PSR Series Pumps

Economical shuttle pumps for recirculation applications up to 100°C (212°F) and 4 Bar (60 psi).

Compatible Legacy Model Pumps

White Knight grounding adapters are also compatible with legacy model pumps. They may be used with AT Series, AP Series, AP FM Series, X Series, PL Series and PLF Series pumps.

High-Purity Closed-Loop Pump Systems

Automatically maintain laminar flow or steady pressure. White Knight closed-loop systems feature metal-free PTFE pumps. They provide stable temperatures, dead-head, and suction lift.

Control your high purity chemical processes and delivery systems. Simplify process automation to save time, resources and reduce costs.

- ≤ 140 lpm (36 gpm) flow rates

- ≤ 7 Bar (100 psi) pressures

- ≤ 210°C (410°F) temperatures

- Maintain stable temperatures

- No metals, no corrosion

- No elastomer O-rings, no leaks

- No electric motors, no heat rise

- No impellers, no microbubbles