High-Purity Valve Manifolds

iPolymer High-Purity Valve Manifolds (HVM) feature 100% virgin PTFE, PFA and M112 wetted flow path ideally suited for aggressive chemical applications common in Semiconductor valve boxes and distribution systems. Their simple, nonmetallic construction consist only of PTFE, PVDF, PFA and PEEK ensuring reliable, long lasting performance. The primary Manual valve directs flow from the common ports to the process port (typically North) and the drain valve allows the operator to purge or sample the process (typically South). iPolymer HVM-8 and HVM-12 are direct replacements for the Parker MV-8 Series valves.

PTFE Manual High-Purity Valves

iPolymer High-Purity Valves (HV) feature 100% virgin PTFE and M112 wetted flow paths ideal for high-purity, high-temperature applications. The HV Series is a multi-turn diaphragm valve available in 1/4, 1/2 and 3/4-in sizes. The simple, nonmetallic external construction consist of only PTFE, PVDF and PEEK to ensure reliable, long-lasting performance in the most aggressive environments. Common applications include DI water, aggressive chemistry distribution, and safety shutoff.

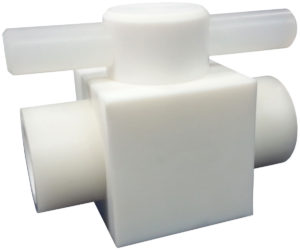

Manual PTFE Ball Valves

iPolymer Ball Valve features an all PTFE wetted surface design. The design is ideally suited for harsh chemical and corrosive media and environments. Polytetrafluoroethylene (PTFE) is ideal for cleanroom and deionized water applications. The body, stem, ball and ports are constructed from PTFE. For standard applications, external non wetted components are constructed from Natural PVDF and Polypropylene.

PTFE Stopcock Valves

Stopcock Valves are precision machined devices that function in much the same way as a ball valve. When the handle points in the direction of flow, the valve is fully open; when the handle points perpendicular to the direction of flow, the valve is fully closed; and at the 45 Degree position the valve is halfway open and thereby has a metering effect on the media flow. iPolymer Stopcock features an all PTFE wetted surface design. The design is ideally suited for harsh chemical and corrosive media and environments. Polytetrafluoroethylene (PTFE) is also well suited to clean room and deionized water applications. The body, stem and ports are constructed from PTFE. For standard applications, external non wetted components are constructed from Polypropylene. All configurations are optionally available as Panel Mounted and/or High Ambient Temperature models.

Obsoleted Manual Valves: Precision Plug Valves, Metering Valves, Sampling Metered Valves