Overview

PTFE pumps with nonmetal flow paths for ultrapure chemical processes. They include an on-board magnetic shuttle for enhance reliability, and low-cavitation checks for applications with high head pressure. The pumps are capable of up to 100°C fluid temperatures and 100 psi air pressures. The pumps are available in two models, PA060 and PA140, which are capable of maximum flow rates of 60 and 130 lpm, respectively.

Features & Benefits

- Process-safe PTFE, PFA flow paths

- Low-Cavitation checks reduce fluid acceleration points in the flow path

- Minimal parts in durable machined design

- Reliable, safe operation with leak-free seals

- On-board magnetic shuttle saves space, prevents stalls, and reduces alarm errors in applications with high head pressure

- Pneumatic Logic™ minimizes liquid pulsation and pump vibration

- Robust bellows enable supply pressure of 7 Bar (100 psi)

- Lubricant-free shifting removes contaminants

- Class 100 cleanroom assembly, testing, and packaging

- No preventative maintenance during warranty

Cavitation Guard™

Minimize cavitation with fewer fluid acceleration points in the flow path.

Flow with Cavitation Guard™

Flow without Cavitation Guard™

Velocity (in/s)

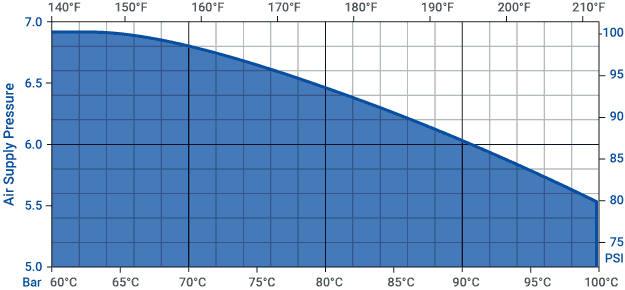

Temperature Limits

Magnetic Detent

This shuttle uses encapsulated rare earth magnets to improve pump reliability and prevent stalls in extreme situations, such as pumping against high head pressure or with low air volume. The magnetic shuttle detent reduces tool alarm errors and process switches to redundant systems. Its non-wearable detent minimizes wear without grease to reduce maintenance costs and eliminate potential contamination.

- Prevents stalls in applications with high head pressures

- Prevents stalls caused by low air volumes

- Reduces tool alarm errors

- Non-wearable detent reduces maintenance costs

- Lubricant-free shifting eliminates potential contamination

- Improved cleanliness over greased designs

Operation

PA Series pumps feature White Knight’s Pneumatic Logic™, which improves performance and reliability by minimizing vibration, pulsation, and wear.

Supply Air

Exhaust Air

Ambient Air

Liquid Suction

Liquid Discharge

Magnetics

Performance & Dimensions

PA060 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PA140 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

Specifications

| Model | PA060 |

PA140 |

|---|---|---|

| Flow Rate* | 60.3 lpm (15.93 gpm) |

129.6 lpm (34.24 gpm) |

| Size of Air Connection | 1/4-in FNPT |

3/8-in FNPT |

| Displacement Per Cycle* | 0.184 L (0.049 gal) |

0.468 L (0.124 gal) |

| Cycles Per Minute* | ≤ 327 |

≤ 277 |

| Weight | 4.7 kg (10.4 lb) |

16.6 kg (36.6 lb) |

| Suction Lift* | ≤ 3 m (10 ft) |

≤ 3 m (10 ft) |

| Sound Pressure** | 73.11 dB(a) 82.50 dB(a) |

81.98 dB(a) 91.60 dB(a) |

| Sound Power** | 64.29 dB(a) 74.11 dB(a) |

76.37 dB(a) 83.16 dB(a) |

| Max Temperature | 100°C (212°F) |

|

| Max Pressure | 7 Bar (100 PSI) |

|

| Fluid Path Materials | PTFE / PFA |

|

| Non-Fluid Path Materials | PTFE / PFA / PP / Ceramic |

|

| Stroke Detection Options | Fiber optic with or without sensor, or solid state pressure switch |

|

| Leak Detection Options | Fiber optic with or without sensor, or conductivity |

|

| Electronic Control | Available |

|

| Model | PA060 |

PA140 |

*May vary by configuration or system. Suction lift diminishes over time. Recommended installation level less than 3 ft above source.

**dB Level at 100 psi 50 CPM (top) and 100 psi maximum CPM (bottom). Sound Levels measured in accordance with ISO9614-2:1997. Contact White Knight for details.