Overview

click+drag to rotate

White Knight PSD Series air-operated double-diaphragm (AODD) pumps, feature PTFE corrosion-resistant fluid paths, which make the pumps ideal for corrosive or toxic liquids such as acids, fuels, glues, paints, resins, inks, or wastewater, as well as more viscous fluids and slurry.

The pumps are available in 3/8, 1/2, 1, or 1-1/2 inch models. They feature high-quality machined designs, unique sealing surfaces, and tight bolt configurations to ensure consistent, reliable performance and superior product containment. They may be configured in various materials to meet most abrasion, temperature, and chemical compatibility requirements. They are dead-head capable and achieve high flow rates while minimizing air consumption and operational noise. The pumps have self-priming, icing-resistant air systems.

PSD Series pumps are easy to install, operate, and service. They can be serviced in the field to minimize repair costs, downtime, and production loss. They require few parts to rebuild and can be rebuilt in situations that would require other AODD pumps to be replaced, which increases pump life and decreases total costs of ownership.

Maintenance required. Schedule depends on duty cycle.

Features & Benefits

- PTFE liquid paths

- Machined design (not molded)

- Icing-resistant air systems

- Removeable air motor

- Positive seat-check improves suction lift

- Self-priming shift mechanism

- In-house engineering and manufacturing

- Polypropylene (PP) pump body

- Over-molded PTFE/EPDM diaphragms

- Dead-head capable operation

- Dry-run, dry-prime capability

- Small footprint, easy to install and service

- Durable, field rebuildable design with minimal parts

- Multiple liquid inlet/outlet directional setups

- Minimizes factory environment noise and operator fatigue

Performance Curves

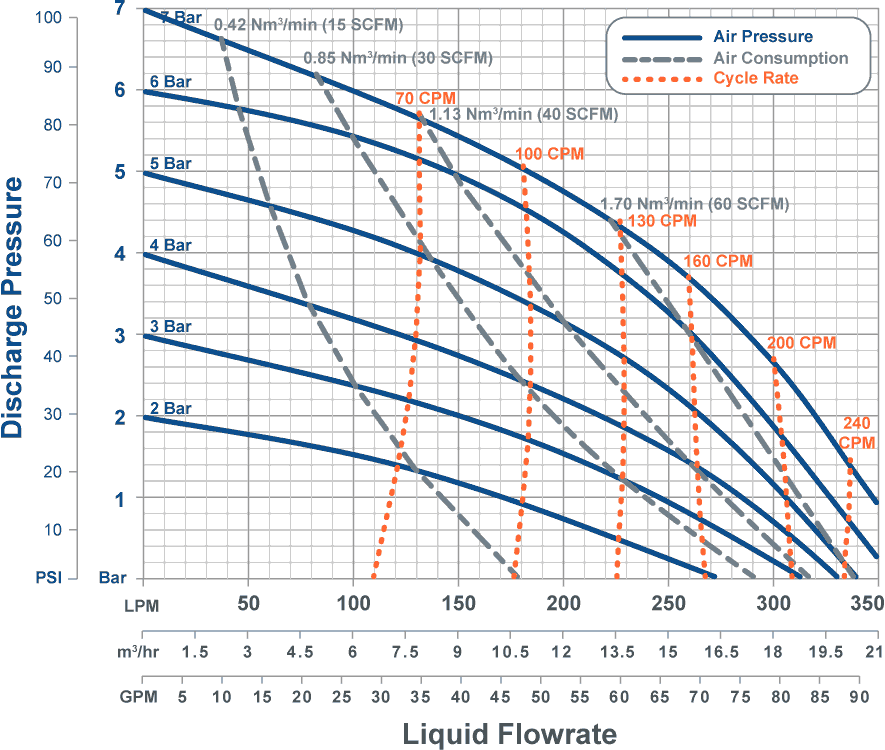

PSD24 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

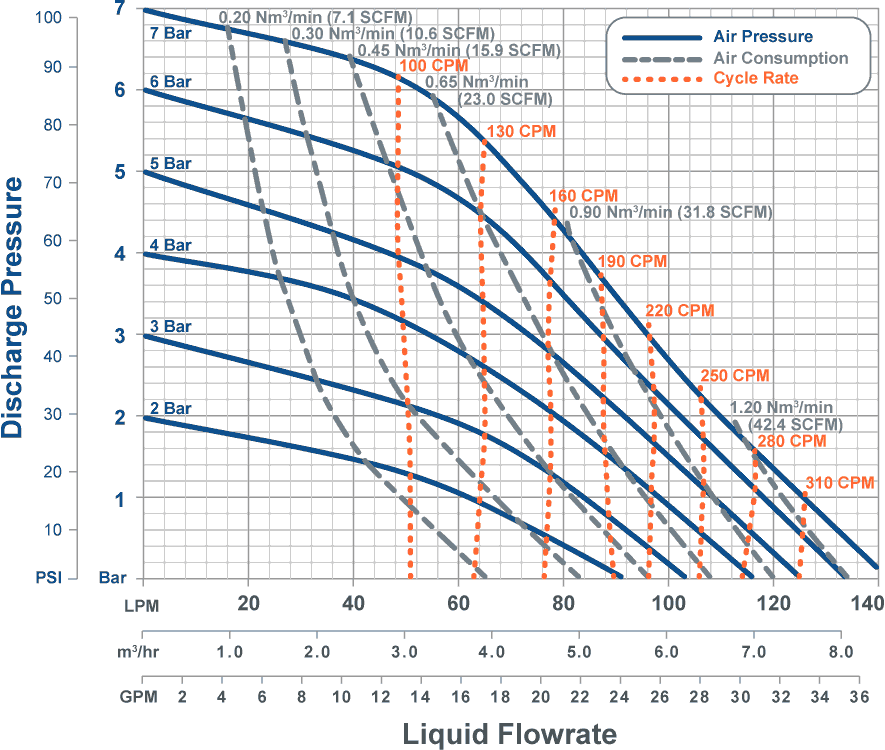

PSD16 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

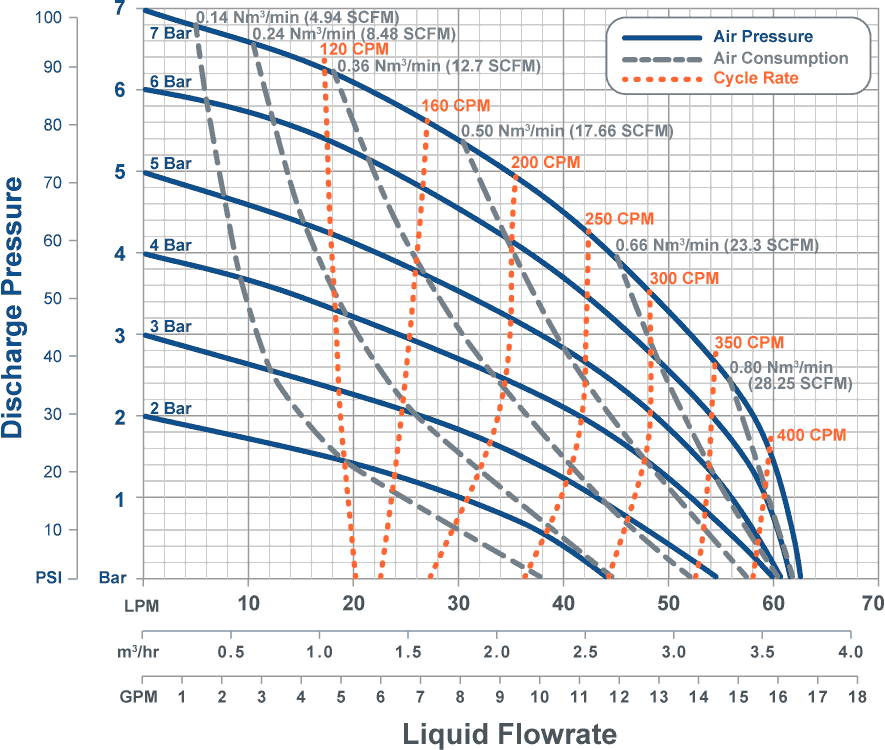

PSD08 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

PSD06 Performance Curves

*Graph is for reference only. Performance was measured utilizing 1/2 in (3/8 in ID) air line and 1-1/4 in (1-1/8 in ID) liquid lines with 1 ft flooded suction. Performance may vary in your system.

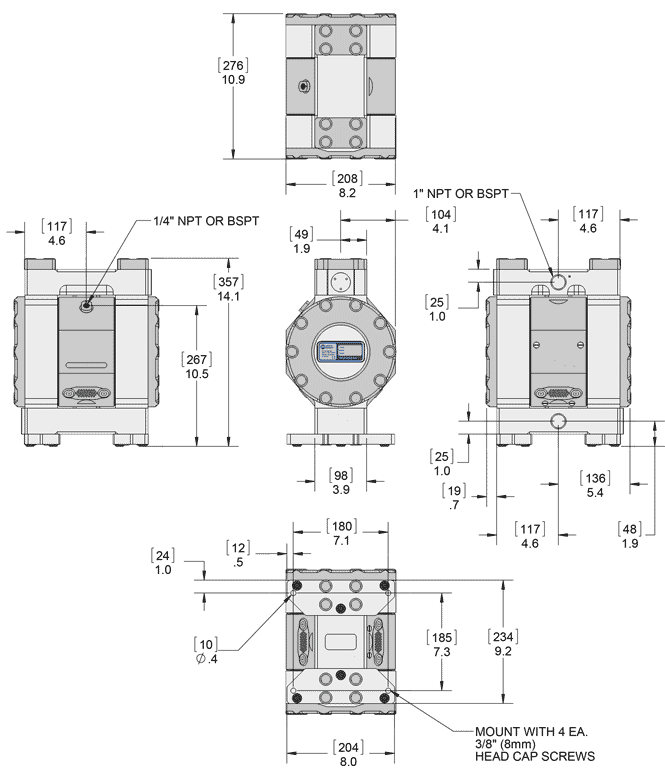

Dimensions

Specifications

Model |

PSD06 |

PSD08 |

PSD16 |

PSD24 |

|---|---|---|---|---|

| Max Flow Rate* | 28 lpm (7.4 gpm) |

63 lpm (16.6 gpm) |

142 lpm (37.5 gpm) |

372 lpm (98.3 gpm) |

| Displacement Per Cycle* |

0.07 l (0.019 gal.) |

0.16 l (0.042 gal.) |

0.56 l (0.148 gal.) |

1.64 l (0.433 gal.) |

| Connections | 3/8 in NPT |

1/2 in NPT |

1 in NPT |

1-1/2 in NPT |

| Max. Size of Passable Solids | 2 mm (0.08 in) |

4 mm (0.16 in) |

5 mm (0.2 in) |

8 mm (0.32 in) |

| Suction Lift Dry* | 3 m (10 ft) |

3 m (10 ft) |

4 m (13 ft) |

5 m (16 ft) |

| Suction Lift Wet* | 9.5 m (31 ft) |

9.5 m (31 ft) |

9.5 m (31 ft) |

9.5 m (31 ft) |

| Sound Pressure** | 60.2 dB(a) 66.1 dB(a) |

61.7 dB(a) 82.0 dB(a) |

66.6 dB(a) 83.3 dB(a) |

84.2 dB(a) 89.8 dB(a) |

| Sound Power** | 51.7 dB(a) 58.1 dB(a) |

54.5 dB(a) 74.8 dB(a) |

61.6 dB(a) 78.3 dB(a) |

83.2 dB(a) 91.1 dB(a) |

| Weight | 3.1 kg (6.8 lb) |

9.0 kg (19.8 lb) |

18.2 kg (40.1 lb) |

43.2 kg (95.2 lb) |

| Max Air/Fluid Temperature | 100°C (212°F) |

|||

| Maximum Air Pressures | 7 Bar (100 psi) |

|||

| Minimum Air Pressures | 2 Bar (30 psi) |

|||

| Fluid Path Materials | PTFE |

|||

| Diaphragm Materials | Over-molded PTFE/EPDM |

|||

| Check Ball Materials | PTFE |

|||

Model |

PSD06 |

PSD08 |

PSD16 |

PSD24 |

*May vary depending on configuration. Suction lift diminishes over time. Minimize height for best performance.

**Sound Levels measured at 7 Bar 100 CPM (top) and 7 Bar maximum CPM (bottom) in accordance with ISO9614-2:1997.