Pump bellows take the brunt of the workload inside the pump. White Knight’s unique, long-lasting bellows design has been developed over many years utilizing our vast experience manufacturing with PTFE. They are made entirely in-house from the finest, 100% pure PTFE powder – which makes them ideal for handling harsh chemicals used in wafer fabrication processes.

White Knight’s highly-engineered bellows provide for over 200 million cycles. They last longer than any other fluoropolymer bellows or diaphragm, and are proven in the field and White Knight’s test lab.

Bellows Material

Fluoropolymers (PTFE and PFA) have good flexural qualities, but are weaker than rubber and elastomers. Special tooling and machining practices have been developed to hold extremely tight tolerances in critical areas of machined bellows. This combined with highly engineered formulas for flute depth, width, and wall thickness, as well as the use of fluoropolymers, all contribute to the superiority of White Knight bellows. The selection of materials used for bellows involves comparison of properties and cost. Sintering (baking) formulas also determine whether a finished part has higher structural stability or greater flexural characteristics. Proper sintering procedures ensure the perfect combination of properties for extremely long lifespans.

Bellows Quality

White Knight has bellows in the field with 200+ million cycles – longer than the advertised life of competitor pumps. We have developed time-tested methods that are based on formulas which consider flute depth, width, radius and wall thickness, and material purity to maximize the lifespans of our bellows. These factors determine how well the material will react to continuous expansion and contraction. To ensure the quality of our bellows, we routinely dissect, measure and examine samples. White Knight bellows are assembled into our pumps, tested and packaged in class 100 clean rooms. For more information on bellows quality, see the advantages: In-House Quality Control, Pump Materials, Consistent Quality PTFE, Product Testing, and Warranty.

White Knight makes use of thick-wall bellows with tapered ends as well as bellows with standard wall thickness and non-tapered ends.

Tapered Bellows

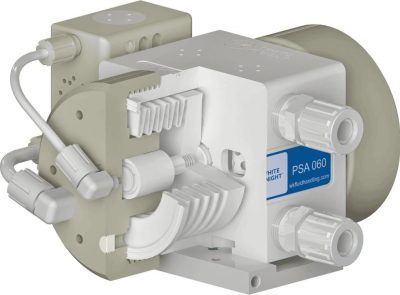

White Knight thick-wall bellows with tapered ends are more robust and prevent bellows from overextending while shifting. White Knight provides 2-year warranties on all pumps with tapered bellows, including the PSU, PSH, PSA, PFU, PFH, PFA, PXU, PXH, and PXA Series pumps as well as the PL, PX, and PLF legacy model pumps. The Thick-Wall Design is part of the qualifier for pumps capable of use in pressures up to 7 Bar (100 psi).