Overview

White Knight PTFE and PFA pulse dampeners reduce pulsation, improve flow control and increase batch yields. These in-line and top mount dampeners protect system components such as filters, fittings and pipes to minimize downtime for repairs.

Top-mounted DBA030 pulse dampener with PSA030 ambient temperature pump.

In-line DBU060 pulse dampener with

PSU060 ultra-high temperature pump.

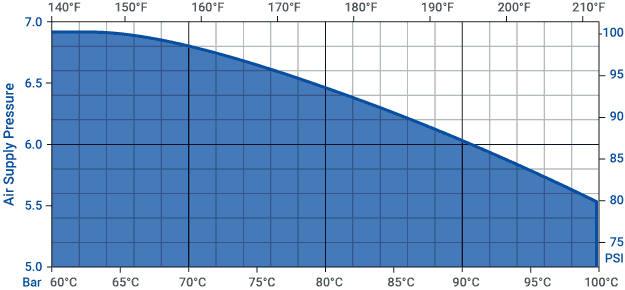

DBA Series Pulse Dampeners

Designed for PFA, PSA and PXA Series pumps capable of pressures up to 7 Bar (100 psi) and temperatures up to 100°C (212°F).

DBH Series Pulse Dampeners

Designed for PFH, PSH and PXH Series pumps capable of operating at pressures up to 5.5 Bar (80 psi) and in temperatures up to 145°C (293°F).

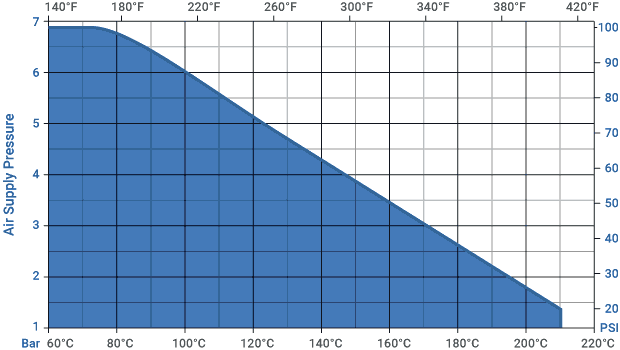

DBU Series Pulse Dampeners

Designed for PFU, PSU and PXU Series pumps capable of operating at pressures up to 7 Bar (100 psi) and in temperatures up to 210°C (410°F).

Specifications

Model | ||||||||

|---|---|---|---|---|---|---|---|---|

Max Fluid Temperature | 100°C (212°F) | 100°C (212°F) | 100°C (212°F) | 145°C (293°F) | 145°C (293°F) | 145°C (293°F) | 210°C (410°F) | 210°C (410°F) |

Max Supply Air Pressure | 7 Bar (100 psi) | 7 Bar (100 psi) | 7 Bar (100 psi) | 5.5 Bar (80 psi) | 5.5 Bar (80 psi) | 5.5 Bar (80 psi) | 7 Bar (100 psi) | 7 Bar (100 psi) |

Pulsation Removed | ≤ 76% | ≤ 84% | ≤ 93% | ≤ 76% | ≤ 84% | ≤ 93% | ≤ 76% | ≤ 84% |

Compatible Pump Models | ||||||||

Cv (in-line only) -with I030 base -with I060 base -with I140 base | 3 14 n/a | 3 14 28 | n/a 14 28 | 3 14 n/a | 3 14 28 | n/a 14 28 | 3 14 n/a | 3 14 28 |

Min Air Consumption (SCFM)* | 0.2 | 0.2 | 0.6 | 0.2 | 0.2 | 0.6 | 0.2 | 0.2 |

Max Air Consumption (SCFM)* | 3.5 | 4.0 | 5.6 | 3.5 | 4.0 | 5.6 | 3.5 | 4.0 |

Fluid Path Materials | PTFE/PFA | PTFE/PFA | PTFE/PFA | PTFE/PFA | PTFE/PFA | PTFE/PFA | PTFE/PFA | PTFE/PFA |

Model |

*Utilizing same size pump at 100 psi / 20 psi

High-Purity Closed-Loop Pump Systems

Automatically maintain flow or pressure with metal-free closed-loop control systems capable of high temperatures, high pressures, high flow rates, dead-head and suction lift!

White Knight’s closed-loop systems provide complete control of high-purity chemical processes and delivery systems. They simplify process automation to save customers’ time and resources, and they reduce costs by eliminating the need for expensive pressure systems.

- ≤ 140 lpm (36 gpm) flow rates

- ≤ 7 Bar (100 psi) pressures

- ≤ 210°C (410°F) temperatures

- No metals or elastomer O-rings

- No impellers or electric motors

- Maintain stable temperatures